[ad_1]

In yesterday’s post, I shared Part 1 of how to make lined, pinch-pleated curtains. You can click here to see Part 1 of this tutorial. Today, I’ll finish up that tutorial and show you every detail of how to finish the curtains and hang them. I want to say up front that this post contains an absurd amount of photos (74 to be exact), but please don’t let that intimidate you! This process isn’t difficult at all, but I wanted to include lots of photos so that you could easily understand every little step of the process. But again, adding pleats and finishing up a drapery panel is not difficult. Just take it one small step at a time, and you’ll get it!

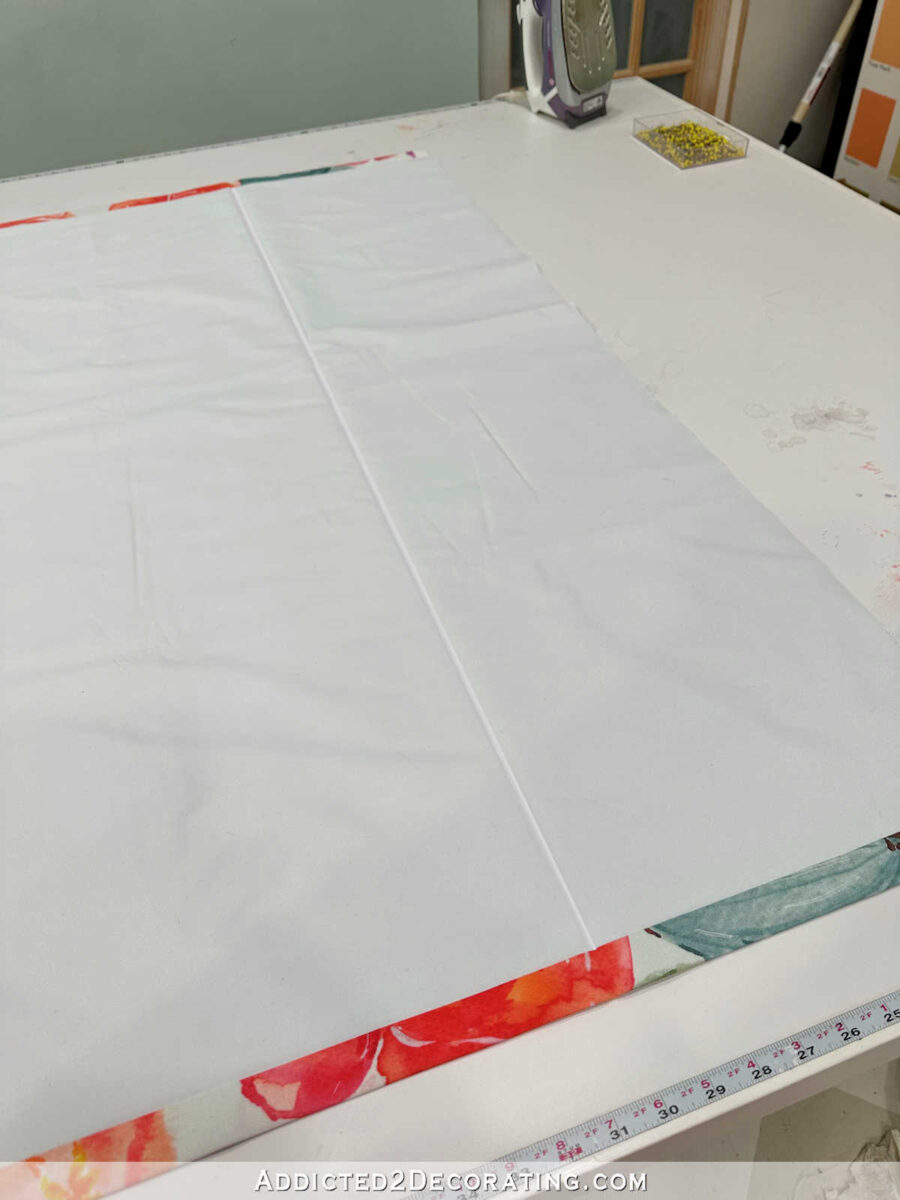

Yesterday, I left off with the body of the drapery panel finished for the most part, and spread out on my work table like this. The hems were finished, the face fabric and the lining had been sewn together, and I was almost ready to tackle the pleated header.

The one thing I still needed to do before working on the pleated header was to iron in the side seams to get that really sharp crease on the side edges of the panel. I really took my time with this and didn’t rush this step because these sides have to be right in order for the drapery panel to hang properly. And again, that lining needs to extend all the way to that outside ironed-in crease along the very edge. All of the folds are in the fabric, not on the lining.

With those sides ironed and the panel lying flat, face fabric down and lining up, I measured and marked my finished drapery length. If you’ll remember, I had taken this measurement right at the very beginning. You can refer back to Part 1 if you don’t remember.

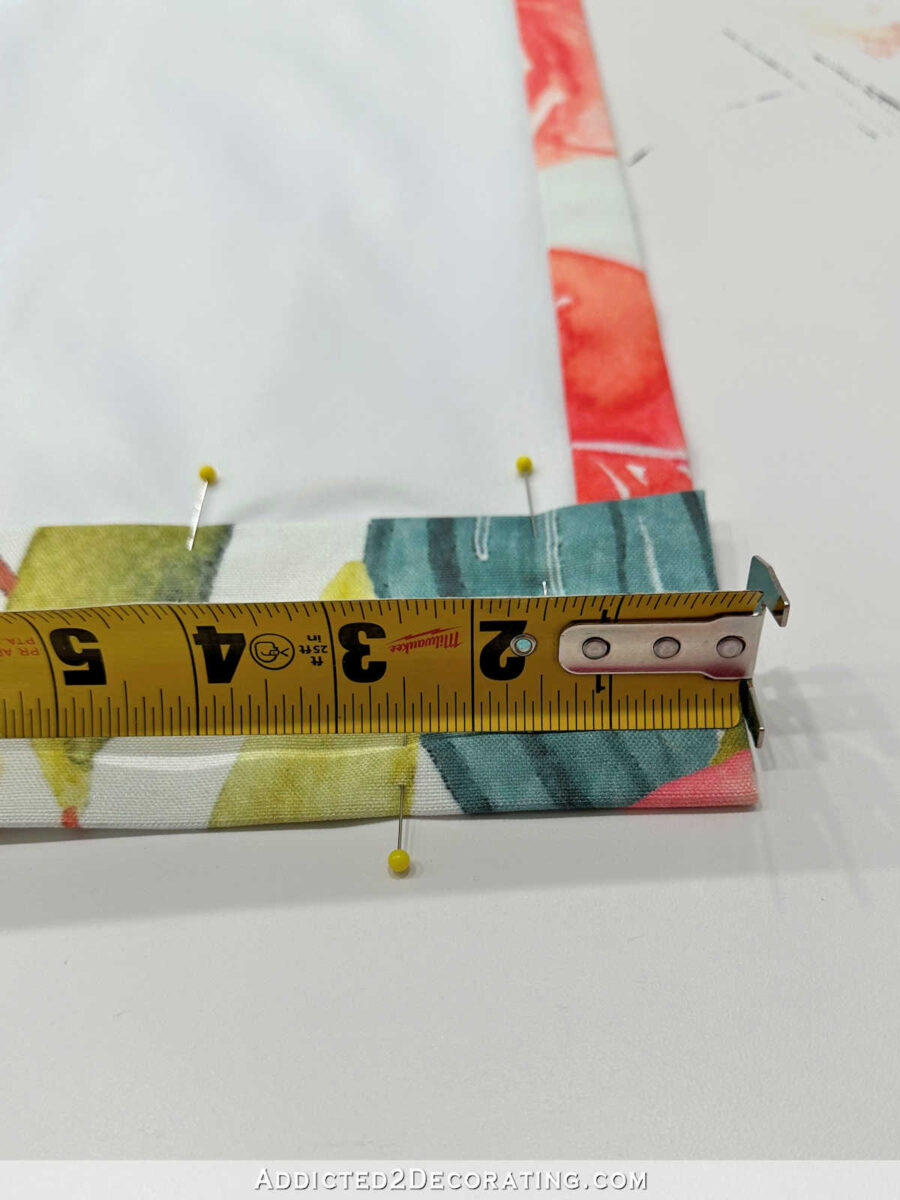

My finished drapery panel length was 88 5/8 inches, so I measured and marked each side of the panel with a pin at that measurement.

For now, I just did one measurement and one pin on each side of the panel.

Next, I folded the fabric over right at those pins and repinned each side into place through all layers of the fabric.

And then I measured and pinned the finished height on the rest of the panel.

I only needed to make only slight adjustments in the fold as I moved my way across the top of the panel.

Once I had the entire top folded to the correct measurement and pinned into place, I steam ironed that fold in the top, removed the pins, and ironed it again to make sure I had a very sharp crease.

So at this point, here’s what the top of the panel looked like from the back — no pins and a very sharp ironed-in fold along the very top edge of the panel.

Next, I unfolded the top and made sure I could see the crease all the way across the panel. (I edited this photo to enhance the line so that you could see it. In person, the ironed-in crease was very easy to see.)

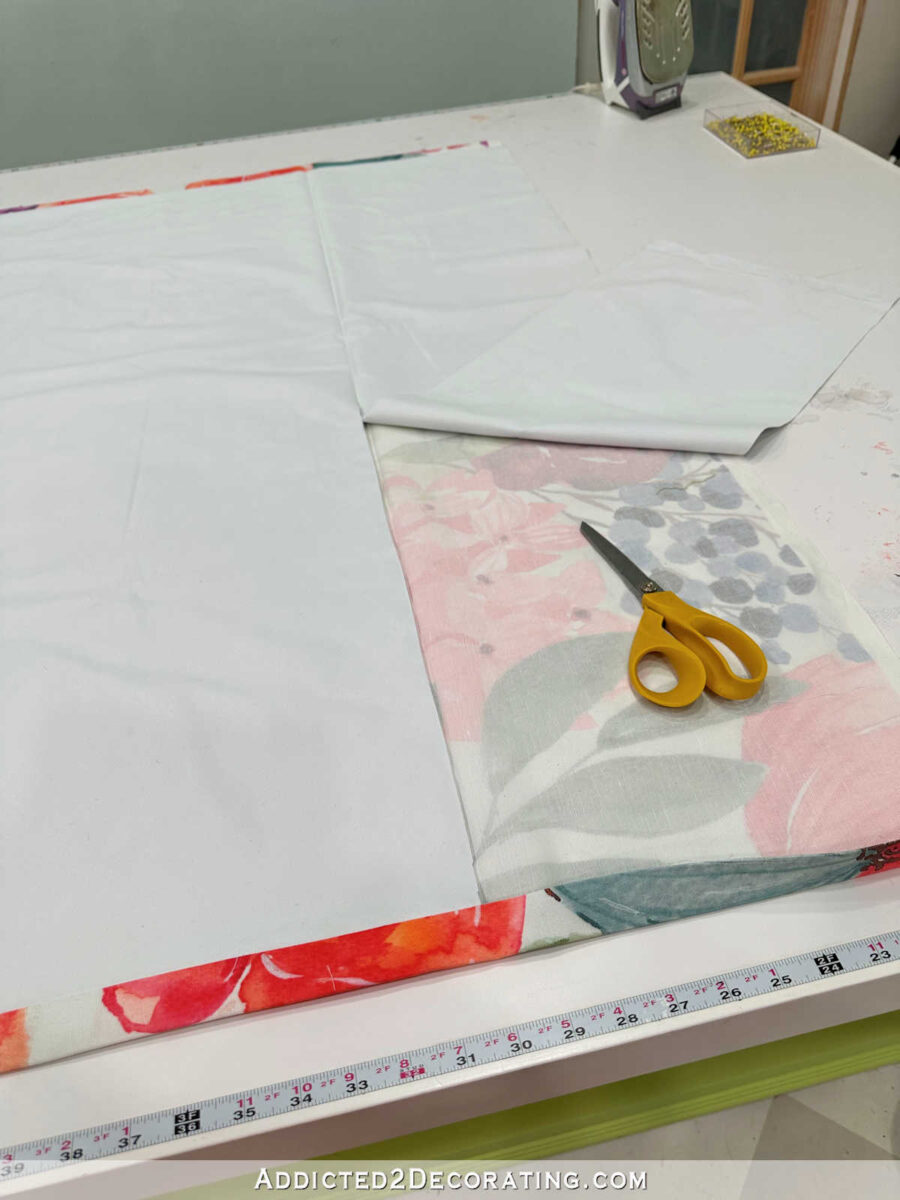

Then I removed the stitching holding the face fabric to the lining from the very top down to that ironed-in crease.

And then I used that ironed-in crease as a guide to cut off the excess lining. I don’t think this is 100% necessary, but I always remove the excess because it will create two additional layers of fabric to wrangle into pleats later, and that just creates unnecessary bulk that makes pleating more challenging than it needs to be.

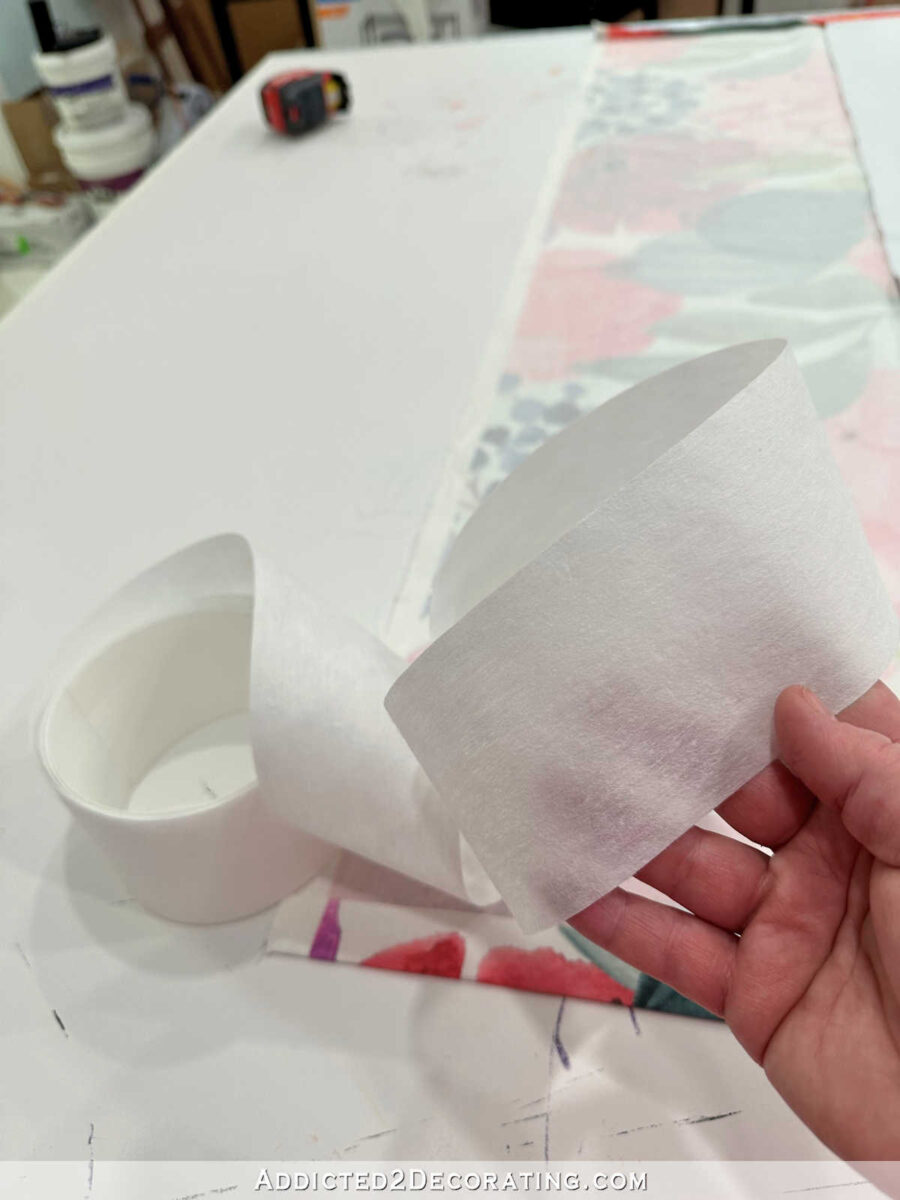

Next, I cut my drapery header tape to length. This is a thick-ish material that feels a lot like a heavy interfacing. You can get it in different widths, but I prefer the three-inch width. You can buy it by the yard at places like Joann Fabrics.

I cut it to length so that it spans the width just inside the 1-inch side folds.

Since my header tape is three inches wide, that meant that I needed to cut away some of the excess fabric at the top. The fabric needs to extend past the top of the cut lining at a measurement equal to two times the header tape width, minus just a smidge. (That’s the technical term for it. ? ) Since I was using three-inch header tape, I cut the fabric to six inches minus a smidge (about 5 7/8 inches) past the cut edge of the lining.

So once I had the excess cut off and it looked like this, I was ready to add the header tape.

I started by placing the header tape so that it lined up along the top of the lining…

And then I folded the fabric down over the header tape along the ironed-in crease…

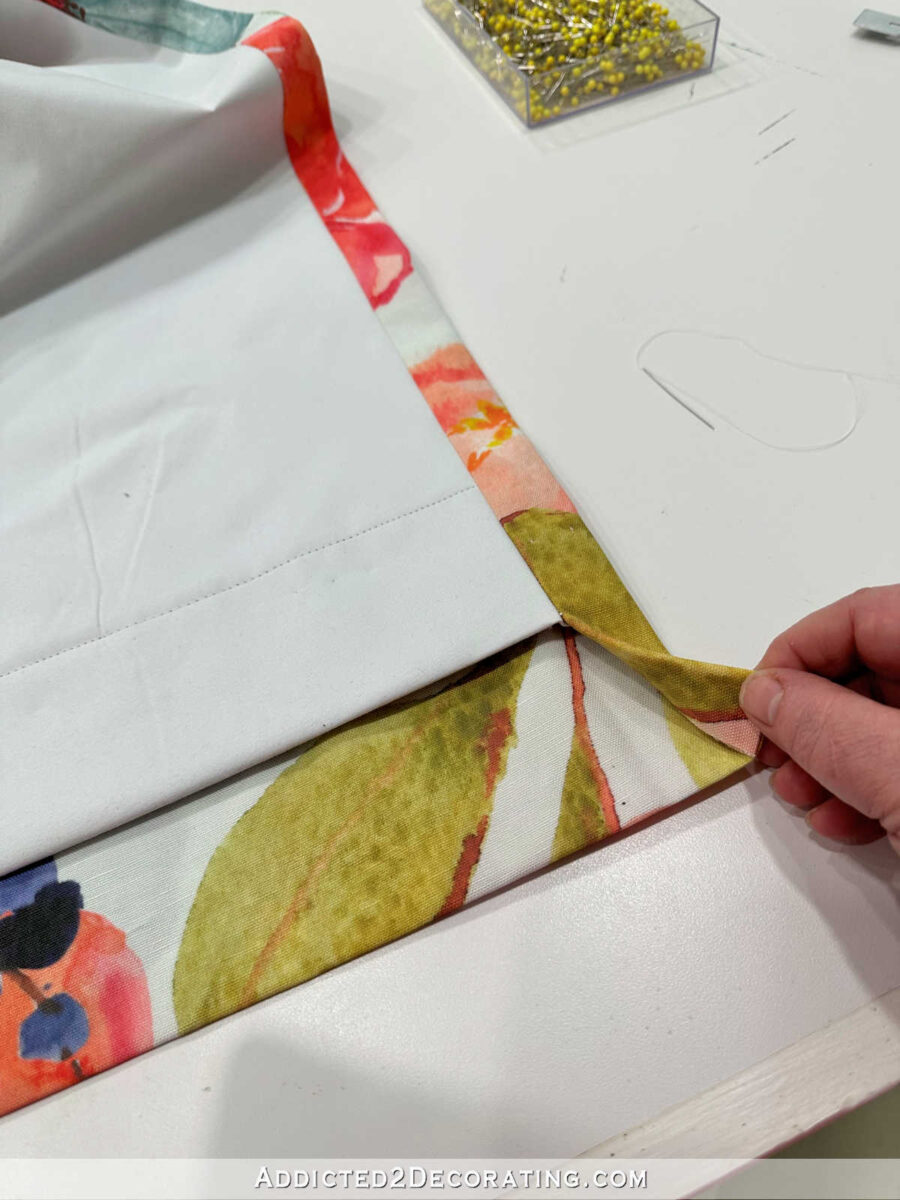

And then starting in the middle and working my way out to the ends, I wrapped the excess fabric back under the header tape so that the fabric enveloped the header tape. And then I pinned all the layers into place.

And here’s what it looked like once it was pinned into place all the way across.

Next, I had to figure the placement of my pleats. The first measurement I needed was the return for the outside edge of the panel. The return is the piece that folds back from the curtain rod and meets the wall. To get this measurement, simply measure from the tiny drapery pin loop on the curtain ring to the wall. It’s hard to see from the perspective in the photo below, but the measurement from the wall to my curtain rod/rings is 3 1/4 inches.

So I took that measurement and marked off 3 1/4 inches on the outer edge of the header.

And then I measured and marked off a space on the leading edge (the inside edge) of the header. I just went with 2.5 inches because I think that looks nice. But you can adjust depending on what you think looks nice.

Or if you’re adding trim to the leading edge of your drapery panel (which needed to be done several steps ago), you might need to adjust this measurement depending on the width of the trim. The last thing you want is getting a decorative trim caught up in your first pleat. Dealing with that bulk in a pleat can be a nightmare, and it pretty much never looks right. Ask me how I know. ? But anyway, about 2 1/2 to 3 inches for that leading edge will do.

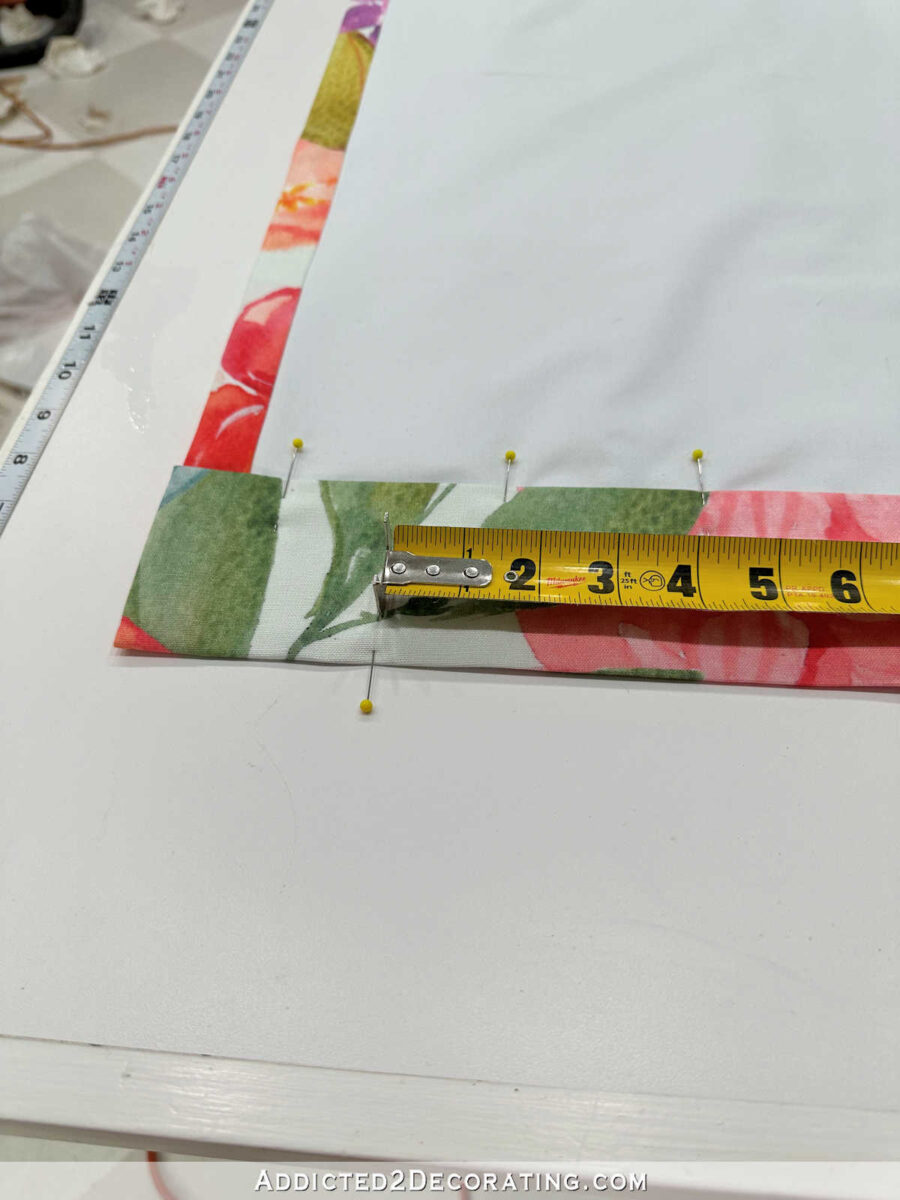

Once I had the return and the leading edge marked off, I measured the width remaining between those pins. So I placed my tape measure right on one of those pins…

And measured to the other one. That gave me a measurement of 43.5 inches. (Again, the perspective on the photo below makes that look a bit off.)

On a single width drapery panel, I like to have seven pleats. And I like to have a minimum of three inches of fabric width to work with per double pleat, or a minimum of 3.5 inches per triple pleat. I decided to use double pleats on these drapery panels, so I multiplied 7 (pleats) times 3 (inches per pleat), which meant that I needed a total of 21 inches for my pleats. That left me with 22 1/2 inches of fabric that needed to be divided by 6 spaces between the pleats. (If I have seven pleats, I would have six spaces. If I have nine pleats, I would have eight spaces. So the number of spaces is always one less than the number of pleats.) So 22 1/2 divided by 6 means that each space needed to be 3.75 inches wide.

So I used my pins to mark off those areas.

Next I needed to pin the pleats so that I could sew them into place. To do this, I folded the fabric so that the to pins marking off the pleat met.

I folded the fabric so that the back sides were together as shown…

And then I removed one of the pins, and pinned all layers together with one pin.

Here’s what that looked like pinned in…

Then I skipped the space next to that pleat…

And moved on to the next area marked off as a pleat, and repeated that folding and pinning process.

So with two pleats pinned in place, this is what it looked like…

I repeated that all the way across until I had all seven pleats pinned.

At this point, those other pins along the bottom of the drapery header tape/folded fabric can be removed. They’ve served their purpose well, but at this point they’ll just be in the way.

So with the pleats pinned into place, this is what they look like from the front. I used my fingers to crease and press the front folds into the header tape before I took the panel to the sewing machine.

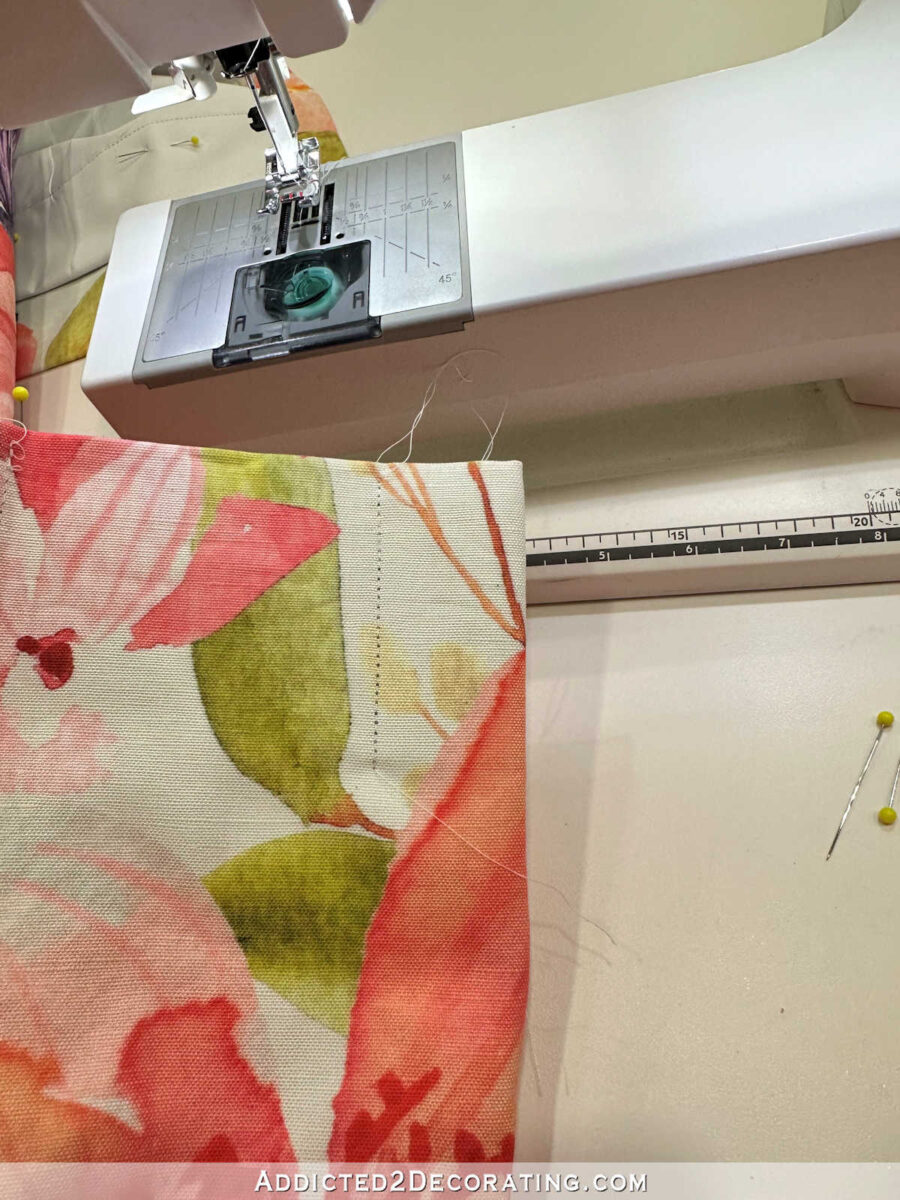

Sewing the pleats into place is done with a basic straight stitch.

To determine where to sew, just divide the pleat fabric width (again, mine was three inches) by two, and sew straight down the header tape from top to bottom at that distance. So I sewed my stitch at 1 1/2 inches from the edge.

And here’s what it looks like with the pleat sewn into place.

I repeated that on the other pleats, and this is what the header looked like with all of the pleats sewn in.

Here’s a side view for a better look.

Those are the basic pleats, but now I had to form the “double” part of the double pleats. To do this, I started my using my finger inside that fold and pressing the seam of the header tape open.

And then I pressed the fold of the pleat down to meet the seam…

And then I brought the two sides up to meet. And that forms the double pleat.

Pleats can be sewn in different places to get different looks. For example, if I sew them into place towards the bottom of the header tape, it results in a more traditional French pleat.

If I sew more towards the top, it gives a bit of a more modern look. This is called a Parisian pleat.

I decided to go with more of a Parisian pleat by sewing the folds together about 3/4 inch from the top, and 1/4 inch from the front folds.

Each sewing machine will be a little different, but this is what the stitch looks like on my sewing machine.

If you don’t have a stitch that looks like that, you can use a wide zigzag stitch with a stationary foot (i.e., set it so that the foot doesn’t walk the fabric forward).

And here’s what the stitch looks like from the side.

And here’s what our double Parisian pleat looks like from the front.

After repeating that process on the other six pleats, my header looked like this…

Only a couple of finishing touches remained. First, I needed to stitch the very ends of the header closed. I personally do this by hand, and not on a machine.

I’m not the very best at hand stitching, but I still think it looks better and cleaner than trying to sew those layers together as close to the edge as possible using a machine.

And then I hand stitch the very bottom corners so that they stay put. At this point, they were still free and not sewn together at all.

I do this by using the least amount of hand sewing possible just because I don’t want it to show.

So since I was using 100% cotton that stays put, I just put a simple tack stitch right on that inner fold and through to the front fabric.

That’s not how I learned to do it in my drapery workroom training, though. So let me show you what I was taught is the proper way, just in case you prefer it.

First, unfold the corner of the fabric like this…

Fold the corner up at a 45-degree angle so that the edge meets that inside ironed-in crease…

And then refold the edge. That gives you a corner that looks like this…

I personally don’t like that. I think it’s unnecessary work, creates the need for additional hand sewing, creates additional bulk. Plus, I just don’t like the way it looks. But that’s a personal preference. You may prefer that way, which of course, is perfectly fine. But I personally just keep mine folded straight, add a tiny little tack stitch to keep the flap of fabric closed, and leave it at that.

The panel is officially finished! To hang the panel, I had to add the drapery pins to the backs of the pleats. Drapery pins looks like this…

They’re inserted right behind each pleat with the hook facing down and the sharp point going up. They just slide right under the stitches holding those pleats together. You’ll get some resistance when putting them in because those stitches should be tight. But if you’re getting a lot of resistance when trying to put them in, you’re probably needlessly forcing the pins into layers of fabric. Just remove the pin and try again.

And I also added a pin on the edge of the outside return, and about an inch from the leading edge…

Then I was ready to hang the panel!

On that return on the outer edge of the panel, I needed to put a small eye hook into the wall right about where I added the black dot below in order to attach that last pin to the wall, but I was all out of eye hooks. Once I get that done, I’ll add the picture here.

Then I needed to crease the spaces between the pleats so that they would stay where I wanted them. As long as there’s no crease in the spaces, that header tape will fight you when you try to properly space your curtain rings.

To do this, I simply brought two pleats together…

And then used my fingers to press in a crease in the header tape on the back.

This will allow the rings to stay where I want them to stay rather than fighting me as I’m trying to make adjustments.

And at this point, the panel was finished and looking beautiful, if I do say so myself! ?

You can decide at this point whether you want a more casual look, like what is shown in the picture above, where the folds in the fabric look kind of carefree and are left to do what they naturally want to do.

Or if you want a more formal, polished, tailored look, you’ll need to “train” your pleats and folds. Do this by starting at the top and patiently folding the fabric in line with the pleats. Once you get about a foot or two down the panel, use some scrap fabric to tie the folds into place.

Continue working your way down until it’s tied in about three or four places and looks like this…

You can leave it like that for a day or two, or you can speed up the process by using a clothes steamer or steam iron to steam in those folds.

And once those folds are trained, it’ll look more like this…

I generally don’t like my creases too creased (as they look above), so once they’ve had a few days like that, I’ll generally get my steam iron and hit them with some steam while smoothing them out a bit so that they look more like gentle waves in the fabric instead of harsher folds bordering on creases. But you’ll have to determine what your panel needs based on your personal taste as well as the fabric that you used.

I’m not sure which look I prefer yet, but I’m leaning towards the first one for my studio. If I decide to go that direction, I can just use my steamer to get those folds out, and then floof the panel like a bridesmaid floofing a bride’s wedding dress and train, and that’ll return it back to that more natural, carefree look.

I hope this tutorial was helpful! If you have ANY questions about the process, please let me know and I’ll do my very best to answer.

Addicted 2 Decorating is where I share my DIY and decorating journey as I remodel and decorate the 1948 fixer upper that my husband, Matt, and I bought in 2013. Matt has M.S. and is unable to do physical work, so I do the majority of the work on the house by myself. You can learn more about me here.

[ad_2]

Source link